A parting tool is a cutting tool used on a lathe to remove material from a workpiece. It is inserted into the lathe chuck and held against the spinning workpiece. The cutting edge of the parting tool cuts into the workpiece, removing a small amount of material with each pass.

The angle of the cutting edge is important in determining how well the parting tool works. A sharper angle will result in a narrower cut, while a more acute angle will produce a wider cut. The depth of the cut can be controlled by adjusting the position of the tool relative to the workpiece.

Parting tools are typically made from high-speed steel or carbide for better wear resistance. They are available in various sizes and shapes to suit different applications.

Metal Lathe Tutorial 15: Parting

Table of Contents

- First, find a piece of metal that is the right size and shape for your needs

- Next, use a file to sharpen the edge of the metal so it is nice and sharp

- Once the edge is sharp, use a hammer to strike the metal and create a small indentation in the center of the edge

- Finally, use a drill bit to create a hole in the center of the indentation so you can attach it to your lathe tool

Metal Lathe Parting Tool Angles

A metal lathe is a powerful machine used to create parts and products from raw metal stock. It relies on various cutting tools to shape the metal to the desired dimensions. One of these cutting tools is the parting tool, which is used to create clean, sharp cuts in the metal.

When using a parting tool, it’s important to maintain the correct angle between the tool and the workpiece. This ensures that the cut is clean and doesn’t cause damage to either the tool or the workpiece. The angle also affects how deep the cut will be, so it’s important to adjust accordingly.

There are a few different angles that can be used when cutting with a parting tool, but 45 degrees is generally considered ideal. This angle can be adjusted slightly depending on the specific application and material being cut. Experimentation is often necessary to find what works best in each situation.

No matter what angle you use, always remember to keep your cuts shallow at first. This allows you to get a feel for how the parting tool behaves and prevents any mistakes from being too difficult or costly to fix. With practice, you’ll be able to produce clean, precise cuts with ease!

Credit: www.youtube.com

What Angle Should a Parting Tool Be?

There are a few schools of thought on what angle a parting tool should be, but the most popular seem to be between 15 and 30 degrees. Some people prefer a 15 degree angle for general use, while others find that a 30 degree angle works better for them. Ultimately, it comes down to personal preference and what feels comfortable for you.

If you’re just starting out, we recommend trying both angles and seeing which one works better for you. Experiment with different techniques and see what gives you the best results. There’s no wrong answer here – it’s all about finding what works best for you!

How Do I Cut a Parting Tool?

A parting tool is a cutting tool used in woodworking to create a narrow groove or channel, typically for the purpose of separating two pieces of wood.

There are several ways to cut a parting tool, depending on the specific project you are working on. For example, if you need to create a very precise and clean cut, you might use a handheld power saw with a sharp blade.

However, if you are working with thinner pieces of wood or need to make more intricate cuts, you might opt for using a hand-held router or even a chisel.

No matter which method you choose, it is important to take your time and work slowly and carefully so that you don’t accidentally damage the piece of wood you are working on. When in doubt, it is always best to err on the side of caution and go slower rather than faster!

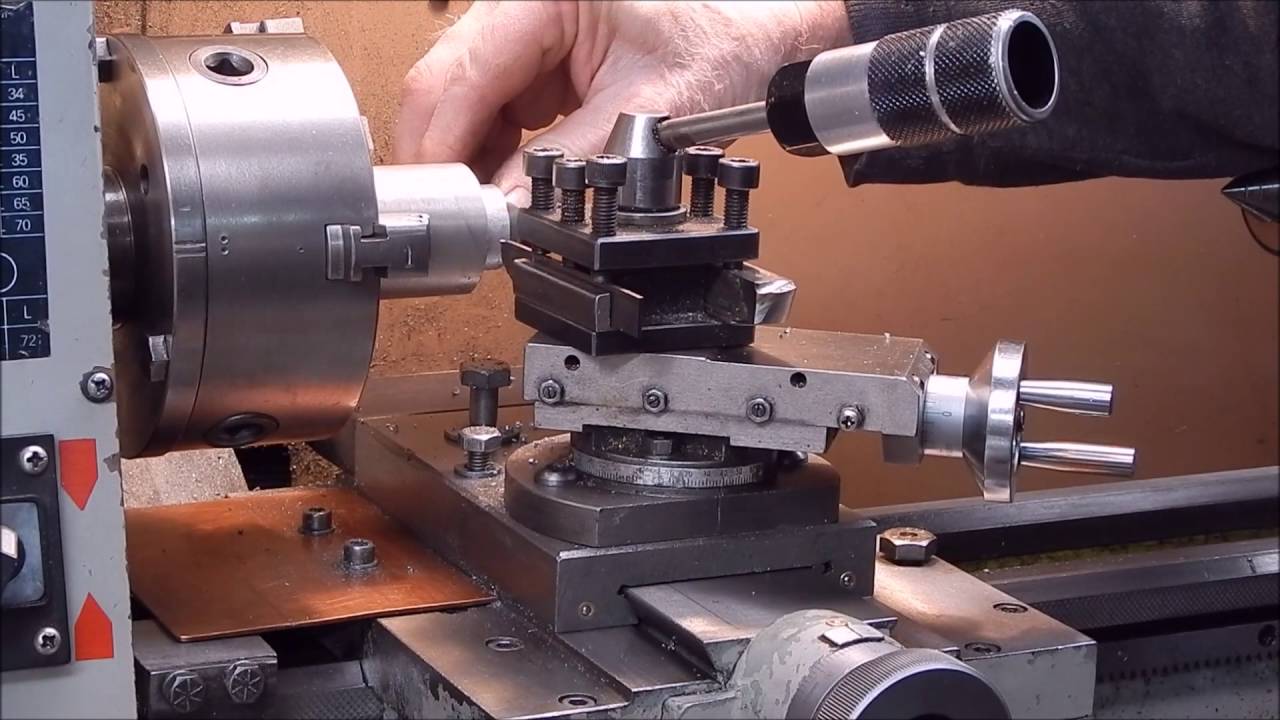

How Do You Use a Parting Tool on a Metal Lathe?

Assuming you would like a blog post discussing how to use a parting tool on a metal lathe:

A parting tool is used on a lathe to cut grooves and do other finishing work on cylindrical objects. The cutting edge of the parting tool is set at an angle to the workpiece, so that it cuts into the side of the workpiece as it is rotated.

To use a parting tool, first set the cutting angle using the toolpost. Next, bring the cutting edge of the tool close to the workpiece without touching it. Start the lathe and slowly feed the tool into the workpiece until it reaches the desired depth.

Finally, reverse direction and withdraw the tool from the workpiece.

What is a Parting off Tool Made Of?

A parting off tool is a cutting tool used in lathes to remove material from workpieces in small, controlled amounts. The tool is inserted into the chuck of the lathe and held at a fixed position while the workpiece rotates. As the cutting edge of the tool comes into contact with the workpiece, it chips away at the material, slowly removing it from the surface.

The vast majority of parting off tools are made from high-speed steel (HSS), which is a type of carbon steel that contains additional alloys (such as chromium) that increase its hardness and resistance to wear. HSS is an ideal material for cutting tools as it can maintain a sharp edge even at high temperatures, making it perfect for use in metalworking applications.

There are also some solid carbide parting off tools available on the market, which are made from a harder and more brittle material than HSS.

These tools are typically only used in very demanding applications where extremely high precision is required, as they are more likely to break if they experience any sort of shock or vibration during use.

Conclusion

A metal lathe is a powerful machine that can create parts for a wide variety of machines and products. While it is possible to purchase premade parting tools, it is also possible to make your own. This blog post provides clear instructions on how to make a metal lathe parting tool, including the necessary materials and steps.

With your own parting tool, you’ll be able to create clean cuts on any type of metal.