Table saws are an essential tool for anyone who wants to do woodworking. They come in a variety of sizes and can be used for a variety of different tasks. Tenons are one of the most common uses for table saws.

Tenons are essentially wooden dowels that are used to join two pieces of wood together. They can be either round or square, and they are usually made from the same piece of wood as the rest of the project. Table saws make it easy to cut tenons because they have a built-in fence that keeps the workpiece steady as you cut.

A tenon is a type of joint that is used to connect two pieces of wood together. It is very strong and can be used in a variety of different applications. A table saw is the perfect tool for creating tenons, as it allows you to make precise cuts quickly and easily.

There are a few things to keep in mind when using a table saw to create tenons. First, you need to use the right blade. A carbide-tipped blade will give you the best results, as it will stay sharp longer and cut through the wood more easily.

Second, you need to set the fence so that it is aligned with the center of the blade. This will ensure that your cuts are straight and accurate. Finally, take your time and be careful when making your cuts.

Table saws can be dangerous if they are not used properly, so it is important to exercise caution while operating one.

Creating tenons with a table saw is a great way to add strength and stability to any project. With just a little bit of practice, you’ll be able to produce perfect tenons every time!

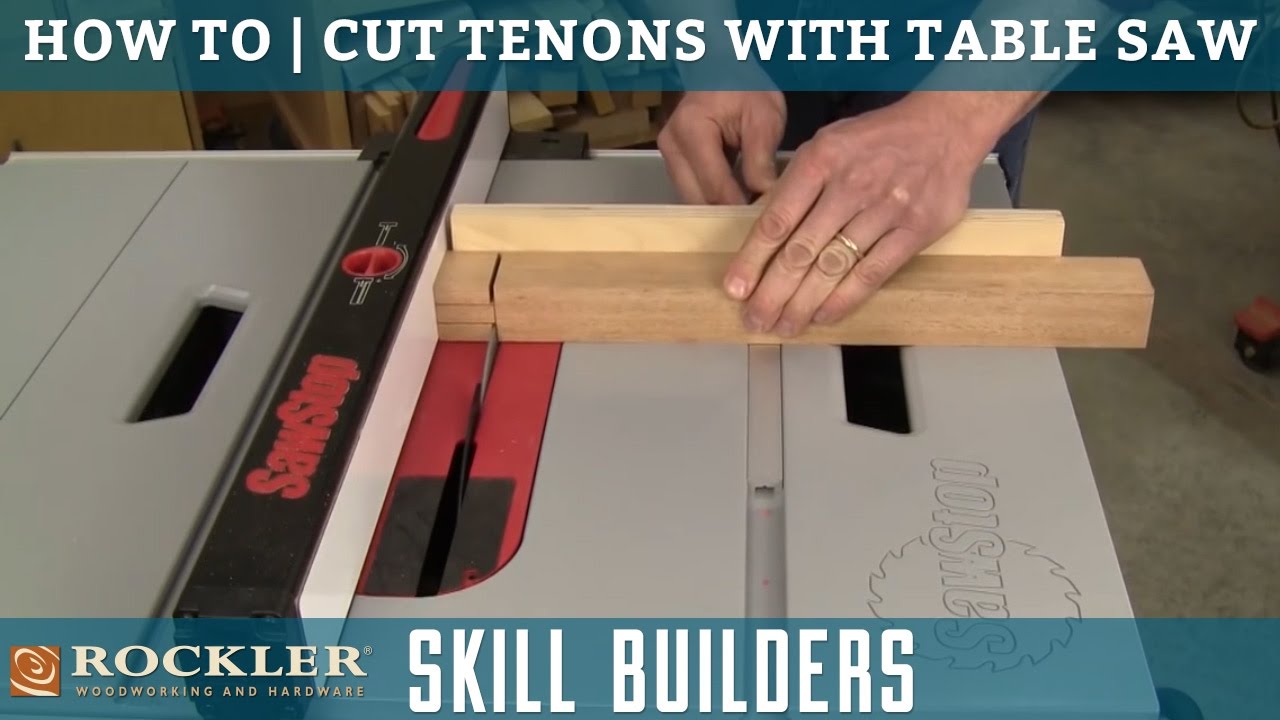

How to Cut Tenons with a Table Saw | Rockler Skill Builders

Table of Contents

What Kind of Saw is Used for Cutting a Tenon?

When it comes to cutting a tenon, there are a few different saws that can be used. However, the most common and effective saw for this job is known as a tenon saw.

This type of saw is specifically designed for cutting tenons, and as such, it features a long and thin blade that is able to make very precise cuts.

Additionally, the handle of a tenon saw is typically offset from the blade in order to give the user more control over the cut.

While there are other types of saws that could technically be used to cut a tenon (such as a handsaw or even a jigsaw), they are not nearly as effective or efficient as a tenon saw. So if you need to cut a tenon, be sure to use the right tool for the job – grab yourself a tenon saw!

How Do You Cut Wooden Tenons?

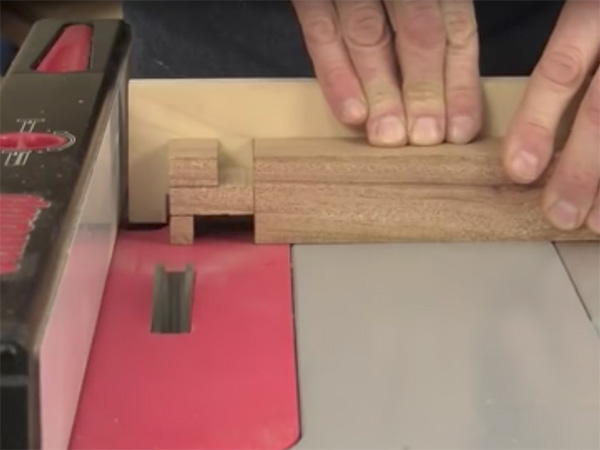

There are a few ways to go about cutting wooden tenons, and the method you choose will depend on the tools you have available as well as your personal preferences. If you have a table saw, the easiest way to cut tenons is by setting up a dado stack and making repeated passes until the tenon is the right size. You can also use a band saw or jigsaw to cut out the basic shape of the tenon, and then use a chisel and/or router to clean up the edges and get it to the final size.

If you don’t have access to power tools, or if you prefer working with hand tools, there are still ways to cut tenons. One option is to use a dovetail saw and coping saw (or even just a regular handsaw) to remove most of the waste material, and then clean up the rest with chisels. This method takes a bit more time and patience, but it can be done entirely without any powered tools if necessary.

No matter which method you choose, there are a few things to keep in mind when cutting wooden tenons. First, make sure that your cuts are perpendicular to the grain of the wood; otherwise, your joint may not be strong enough. Second, take care not to make your cuts too deep; leaving just a little bit of extra material is better than cutting into the adjoining piece of wood.

And finally, take your time; rushing through this process could result in an inaccurate or poorly-fitting joint.

Can You Cut Mortise With a Table Saw?

You can most certainly cut a mortise with a table saw. The main thing you need to be aware of is that the blade needs to be at the correct angle, and that you’ll need to use a dado stack or a special Mortising Attachment.

If your saw has an adjustable fence, you can use that to help set the blade at the right angle.

For most table saws, the ideal blade angle for cutting mortises is around 45 degrees.

Once you have the blade at the correct angle, you’ll need to make sure it’s properly positioned in relation to the workpiece. This will vary depending on whether you’re using a dado stack or a Mortising Attachment.

If using a dado stack, position the workpiece so that one side of the mortise is flush with the outside edge of the dado stack. If using a Mortising Attachment, position the workpiece so that the center of the mortise lines up with the center line ofthe attachment.

Once everything is lined up correctly, slowly lowerthe blade into place and start cutting.

Rememberto go slowly and carefully – this isn’ta race! – and take your time untilyou get comfortable withthe process.

Can You Cut Tenons on a Bandsaw?

One of the great advantages of a bandsaw is its ability to cut various types of joints, including tenons. Tenons are commonly used in furniture construction and can be cut using different methods, such as a dado stack or a table saw with a fence. However, cutting tenons on a bandsaw is a much simpler process that doesn’t require any special equipment.

To cut tenons on a bandsaw, start by marking out the desired width and depth of the tenon on your workpiece. Then, set up your bandsaw with a blade that has at least three teeth per inch. Next, adjust the fence so that it’s positioned just below the centerline of the blade.

Finally, make sure the workpiece is securely clamped to the table before beginning to cut.

When cutting, start slowly and gradually increase your speed as you get more comfortable with the process. It’s also important to keep an eye on your fingers and make sure they’re well away from the blade at all times.

Once you’ve completed the cut, sand down any rough edges and test fit the tenon in its intended joint to ensure it’s snug.

Credit: www.woodworkersjournal.com

Tenoning Jig for Table Saw Plans

Making a Tenoning Jig for Your Table Saw

A tenoning jig is a great way to make strong, precise cuts on your table saw. With a little time and effort, you can build your own jig that will work just as well as any store-bought model.

Here are the steps you’ll need to follow:

1. Decide what size and shape you want your jig to be. There are many different designs out there, so take some time to browse through plans or photos online to get an idea of what will work best for your needs.

2. Cut the pieces for your jig out of plywood or MDF using a band saw or jigsaw. Be sure to wear protective gear while doing this, as the dust can be harmful if inhaled.

3. Assemble the pieces of your jig according to the chosen design, using screws or nails to secure them in place.

If you’re unsure of how it should go together, consult the plans or look at photos online again for reference.

4. Once everything is assembled, sand down all the rough edges and apply a coat of paint or varnish if desired. Let it dry completely before moving on to the next step.

5 . Attach the fence to your table saw using bolts, washers and nuts (or whatever method is specified in the plans).

Tenon Jig for Dewalt Table Saw

If you’re looking for a great way to make precise, clean cuts on your Dewalt table saw, then you need a tenon jig. A tenon jig is a specialized tool that allows you to make perfect cuts for creating tenons (the part of a joint that fits into a mortise).

There are many different brands and styles of tenon jigs available, but they all essentially work in the same way.

You start by clamping the jig onto your workpiece, then use the guide rails to guide your saw blade along the desired cut line.

Most tenon jigs also have an adjustable stop block so you can control the depth of your cut. This is important because you need to make sure that your tenons are all the same size in order for them to fit snugly into their corresponding mortises.

Whether you’re building furniture or just doing some general woodworking, a tenon jig is an invaluable tool to have in your shop. And with a little practice, you’ll be churning out perfectly cut Tenons in no time!

Best Tenon Jig for Table Saw

A tenon jig is an essential tool for anyone who owns a table saw. It allows you to cut perfectly fitted Tenons on the ends of your boards, which are necessary for many woodworking projects. There are many different types and brands of tenon jigs available, so it can be difficult to choose the best one for your needs.

In this blog post, we will provide detailed information about the best tenon jigs for table saws, based on our findings from extensive research. We hope that this will help you choose the right tenon jig for your next project!

Conclusion

If you’re looking for a table saw that can make perfect tenons, look no further than the Bosch GTS1031. This powerful little saw has all the features you need to make clean, precise cuts, and it’s small enough to fit in most shops. The GTS1031 comes with a built-in fence system that adjusts quickly and easily for making different types of cuts.

And because it’s a Bosch tool, you know it’s built to last.