People love to decorate their house, and wooden materials are the first choice for them. However, besides the decoration in some situations, we have to think about safety. Such as to make a dining table, stair railing, balcony railing, etc. In making all these things, Wood enhances the beauty and ensures safety.

Today we are speaking about how to join 4×4 wood. This is a standard post size. We must remember the 4X4 post is very strong to use vertically and used in railing but not that much secure to use it as a beam.

People use many processes and formats to connect the posts together. Here we explain the best two strong and popular methods for joining posts. First, we will explain the tools that we need to do the task; after that, we explain the joining system.

TOP Four Recommended Products

PRODUCT 1: Hitachi Model C10FCG 15 Amp 10 Inch Single Bevel Composite Saw

Table of Contents

The Hitachi power saw provides its users with complete quality when cutting wood or any other material. One of the main advantages you have is that you will have great flexibility when using it. Thanks to its power, you won’t have to put too much pressure and effort on your part.

All users of a saw seek to make life easier by cutting different materials for their projects. With the C10FCG model, you can make completely clean and precise bevel cuts. You should not worry about mobilizing this tool since you can do it too quickly thanks to its weight and lightness.

PROS

- You will not have dust scattered everywhere when you work.

- It has enough space to be able to hold all your material.

- You can get it at a really affordable price.

- Easy to follow instructions are incorporated.

- It is an easy saw to configure.

- Your cuts will be useful, smooth, and straight.

CONS

- You must make sure to assemble the whole saw well to avoid accidents.

PRODUCT 2: DEWALT Miter Saw, Double-Bevel, Compound, 12-Inch, 15-Amp (DWS716)

If you are a user looking for high-quality bevel cuts, the DEWALT Miter Saw is for you. Its recurring users assure that you will not have to buy another saw to cut all kinds of materials with this model of the Genesis brand. You can use this tool to make compound cuts in different materials such as crown molding and shadow boxes.

This Genesis´ saw will provide its users with an affordable price coupled with unmatched benefits. Its versatile size characterizes this saw. Besides, we find information that ensures that it has a design to transport it easily.

Another benefit that this saw gives you is its laser cutting guide that allows you to make cuts quickly. Besides, this saw will enable you to make all your cuts integrated and with greater precision. This tool is recommended for carpentry projects and other types of manufacturing.

PROS

- You can make quick changes to the sheet.

- Your cuts will be characterized by their precision, thanks to the degrees that the saw has.

- You will have a powerful saw with generous support.

- Genesis has designed its light to pick up and healthy.

- It has an innovative design that incorporates wheels for a better method of transport.

- It is designed with strong and resistant material

CONS

- Replacements may take time with the manufacturer

PRODUCT 3: PSI Woodworking LCHSS8 Wood Lathe 8pc HSS Chisel Set

PSI Woodworking LCHSS8 Wood Lathe has a great reputation among users in the industry. This set provides you with steel tools that will help you finish your woodworking projects and other materials in the best way. You will have three tools with different measures to use in your projects, depending on the need.

Recurring users recommend it as it has materials such as high-speed steel. They mention that this tool kit will last up to eight times longer than other types of tools.

With the tools, you get when you buy this set, you can turn wood differently. Thus, you can also give it a Superflute style shape.

One of the most found comments during our research was that they are superior gouges. Your projects also look like they had been developed with high-end tools and without investing so much money.

PROS

- They are made with high-quality material.

- Your tools will be designed by the world’s largest turning tool factories.

- They have an excellent reputation for quality.

- They are sharper tools compared to others of the same size.

- You will have comfortable handles to be able to use them during long days.

CONS

- It is recommended that you always wear a safety mask when using them.

PRODUCT 4: The 3/8” by 1/2” Heavy-Duty Indexable Grooving comes with a carbide insert

This Accusize Industrial product is highly requested and loved by its users. It is recognized for its precision grooving function. This action is usually shallow, but it allows you to perform an exceptional profile turn. In addition, its design with a pressure ring and its raised groove could provide everything you need in your woodworking projects and others in which you need it. Its users place a lot of emphasis on its slots with a wide opening by immersion and precision. It will always happen when holding what you are working with.

We took on the task of looking for this tool and others. However, we chose this one because it is not excessively high in price, but it gives you enormous quality. Also, because this tool could last you years without lowering your work quality, it always gives you pretty good strength when making side cuts.

PROS

- It works very well on rolled steel, whether it is hot or cold.

- It comes with everything you need to make sure you install the tool correctly.

- The approach angle works very well,

CONS

- You will need to polish the tool a bit before using it.

The process how to join 4×4 wood:

1. Connect posts using brackets:

Necessary Tools:

· Two 4X4 wood post

· 4X4 brackets

· Glue

· 2” Decking screws

· Screw guns

· Pencil.

Step-1 Check the basement: We consider the beam as our basement. First, check the beam where we want to set the posts. We must check the head and measure its size. For a beam, the standard size is 6×6. So, we assume that the beam size is 6 by 6.

Step-2 Set the brackets: Secondly, we set the brackets on the beam’s one side and mark the screw points with a pencil. Similarly, mark the other side as well. After that, set the bracket again and filling 2” decking screws with screw gun on the mark points.

Step-3 connect the posts: Finally, we set the two 4 by 4 posts on the beam and Align them properly. Now, filling 2” decking screws with screw gun at both sides of the posts.

This is how we can connect 4×4 posts together with brackets.

2. Connect two posts with nuts and bolts:

Necessary Tools:

· Two 4X4 wood post

· Miter Saw and 18degree protractor

· 5”/6” Nut bolts and washers

· Drill machine and wrench

· Small kneeling brush

· Pencil and sandpaper

READ ALSO : Best Wood Turning Tools In 2021

Step-1. Measure the post for cutting: How to join 4×4 wood

In this process, we can joint independently two posts without using any basement. To do this process, we have to take measures for cutting both posts from the end sides. Use an 18 degree protractor and set a 30 degree or 25 degree angle on both posts and mark a point. Now make a line on the points from one side to another side.

Step-2. Cut the posts:

After making the angles with Pencil, now we have to use the miter saw to make angels at the posts. Set the posts vice-versa. Remember, two angles size must be equal to 4×4 post size. Now sand the cutting surface for smoothing.

Step-3. Drill for nuts and bolts:

Here, we set the posts angle head to another angel head vice versa, and it will look one long post. Now use a drill machine to make three holes for nuts and bolts. The holes intersect into the angel parts of both posts at the same point. From the top, it looks like one hole though there are two posts so that each nut and bolt could connect the two posts strongly.

Step-4. Joint the posts:

Put the bolts and keep washers immediately before nuts into the holes. Then make use of a wrench to tighten the thread as much as you can.

This is how we can connect 4×4 posts together with nuts and bolts.

Joining Two Pieces Of Wood At 90 Degrees

When joining two pieces of wood at a 90-degree angle, it’s important to use a hardwood board that’s at least 4×4. This will provide the necessary strength and stability for the beam connection. To create the joint, first cut the lumber to size and then use a drill to create pilot holes.

Next, insert carriage bolts into the holes and tighten them until the joint is secure. Finally, use a piece of wood or metal to create an obtuse angle so that the joint is reinforced. By following these steps, you can ensure that your wood joinery is strong and long-lasting.

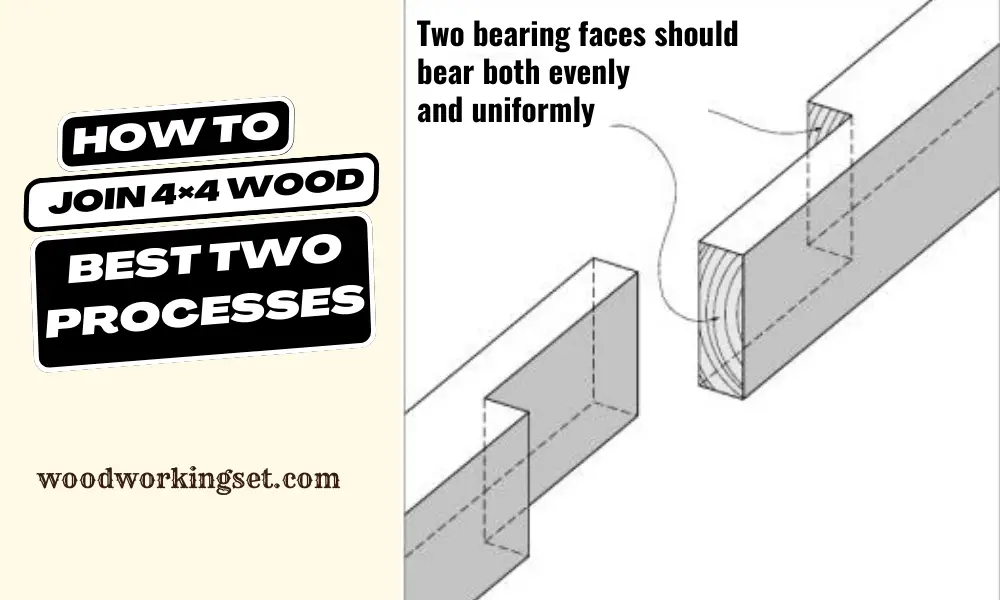

How do you make a half-lap joint on a 4×4?

A half-lap joint is a type of lapped joint where the two pieces of lumber are not edged to edge, but rather overlap each other by half their thickness.

There are many ways to create a half-lap joint on a 4×4. One way would be to use a router with a special bit, or you could use a saw blade specially designed for creating half-lap joints. Another way would be to use a hand saw or chisel to cut out the waste wood between the two boards.

Finally, if you don’t want to make the joint by hand, you can use an electric drill with a lag bolt or structural screw.

What is the strongest way to join two pieces of wood?

The strongest way to join two pieces of wood is by using a flat surface and a lag screw.

First, drill a pilot hole in the middle of the flat surface that will be used as the joining point. Next, place the two pieces of wood that you want to join side-by-side on top of the flat surface. Make sure that the pieces are flush against each other. Now, use a drill bit that is slightly smaller than the diameter of the lag screw to drill into each piece of wood.

Finally, insert the lag screw into the pilot hole and tighten it until it’s secure.

What size hole is needed for a 4×4 fence post?

A 4×4 fence post should have a hole that is at least 5-1/2 inches in diameter and 8 inches deep. If you are using a 90-degree angle, make sure to use a caliper to measure the width of your lumber so you can drill the proper size hole.

When drilling the hole, it is important to use a type of wood that is weather resistant, such as cedar or treated lumber. You may also want to prime and paint your fence posts to help protect them from the elements.

Can you put 6ft fence panels in 4ft posts?

Yes, you can put 6ft fence panels in 4ft posts, but the connection will not be as strong as if you use a dowel joint or a butt joint. A butt joint is the strongest connection because it creates a solid, wooden “beam” across the two posts. A dowel joint is also strong and secure, but less bulky than a butt joint. If you use connectors or screws to join the fence panels to the posts, make sure that they are galvanized or stainless steel so that they do not corrode over time.

VEVOR 4 x 4 Post Base

The VEVOR 4 x 4 Post Base is a must-have for any deck, porch railing, or post holder. This heavy-duty post base is made from 2mm thick steel plate and is powder-coated for extra durability and corrosion resistance. The post base can securely anchor 4×4″ (actual 3.5″x 3.5″ dry post on market) wood posts, making it perfect for a variety of applications.

The post base features a simple and convenient design that is easy to install with the included wrench, 22 sets of 3/8-inch expansion bolts, and 42 sets of self-tapping screws. With its universal design, the post base can be used to fasten a wood post using a post sleeve to increase security. This makes it ideal for a variety of applications, such as deck brackets, porch railings, post holders, and table legs.

The VEVOR 4 x 4 Post Base is a perfect choice for anyone looking to securely anchor wood posts. Its heavy-duty construction and easy installation make it a great choice for a variety of applications.

Q: What is a 4×4 wood?

A: 4×4 wood is a piece of lumber that measures approximately 4 inches by 4 inches.

Q: What is the best way to connect 2 4×4 posts together?

A: There are two commonly used methods to connect two 4×4 posts together: 1. Using a steel plate and bolts or screws: Place a steel plate between the two 4x4s and fasten them together using bolts or screws. 2. Using a half-lap joint: Cut a notch halfway through each post where they meet and secure them together by inserting the notches into each other.

Q: Can I use dowels to connect 2 4×4 posts together?

A: Yes, dowels are a viable option to connect 2 4×4 posts together. Drill two holes into both the posts where they meet and insert dowels into the holes. Apply glue to the dowels before inserting to ensure a strong bond.

Q: Are there other joints I can use to connect 2 4x4s?

A: Yes, other joints you can use to connect 2 4x4s include: 1. Rabbet joint: This involves cutting a groove on the end grain of one post and a corresponding tongue on the end of the other post and fitting them together. 2. Spline joint: This involves cutting a groove or channel in both posts and inserting a spline in between them.

Q: How do I connect two 4x4s end to end?

A: One way to connect two 4x4s end to end is by using a half-lap joint. Cut a notch halfway through each 4×4 where they meet and secure them together by inserting the notches into each other.

Q: What is a pocket-hole screw, and can I use it to connect 4x4s?

A: Pocket-hole screws are special screws used in pocket-hole joinery, which involves drilling angled holes into wood. While they can be used to connect 4x4s, it is not the best method, especially for load-bearing structures. Traditional joinery methods like half-lap joints or dowels are recommended for connecting 4x4s.

Q: Can I connect 4x4s using plywood?

A: While you can connect 4x4s using plywood, it is not an ideal method, especially for load-bearing structures. It is better to use traditional joinery methods like half-lap joints, dowels, or steel plates and bolts.

Q: Can I join pressure-treated 4x4s?

A: Yes, pressure-treated wood can be joined using the same methods as regular 4x4s. However, it is essential to use proper protection like gloves and a respirator when handling pressure-treated wood.

Q: Do I need reinforcement when joining 4x4s?

A: It depends on the intended use. For load-bearing structures like decks or fences, reinforcement is recommended to ensure structural stability. Methods like steel plates and bolts or threaded rods can be used to reinforce the joint.

Q: Is there a jig I can use to join 4x4s more easily?

A: Yes, there are several jigs available that can make joining 4x4s easier. For example, a half-lap jig is used to cut precise half-lap joints, while a pocket-hole jig is used to make angled holes for pocket-hole screws.

Q: Can I glue 4x4s together?

A: Yes, glue can be used to join 4x4s, but it should not be relied on as the only fastener. Use traditional joinery methods like half-lap joints or dowels in addition to wood glue for a strong and durable joint.

What size screws for 4×4 to 4×4

To join two 4x4 pieces of wood, you will need screws that are at least 3-1/2 inches in length. It's recommended to use structural screws or lag bolts for a secure and long-lasting connection. Make sure to pre-drill the holes before screwing them in to prevent splitting the wood.

Conclusion:

It is a prevalent task all over the world. If you work to make stairs railing, balcony railing, yurt platform, and wooden house, you need to know how to connect two 4X4 posts together. You will face this issue. I hope this article supports you in getting a good understanding of this topic.

- 12 Inch Wood Planer: Smooth Your Woodworking Projects Like a Pro - 01/10/2023

- Table Saw Blade: Unleash the Cutting Power - 22/09/2023

- Vintage Table Saw: Uncover the Unparalleled Power - 22/09/2023