A lathe is a machine that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation. Lathes are used in woodworking, metalworking, and other manufacturing applications.To set up a lathe cutting tool, first select the appropriate tool for the material you will be machining.

For example, if you will be machining aluminum, select a carbide-tipped tool. Install the tool in the lathe’s tailstock and tighten it according to the manufacturer’s instructions.Next, adjust the position of the lathe’s carriage so that the cuttingtool is positioned at the correct height.

The cutting tool should be level with the centerline of the workpiece. Finally, engage the lathe’s power feed and slowly advancethe cuttingtool into contact with the workpiece.

LATHE SETUP

Table of Contents

- Select the appropriate cutting tool for the job at hand

- Make sure that the cutting tool is compatible with the lathe model being used

- Install the cutting tool in the lathe spindle according to manufacturer’s instructions

- Set up the workpiece on the lathe chuck or faceplate, making sure it is properly secured

- Bring the cutting tool up to speed and engage it with the workpiece using light cuts until both are spinning at consistent speeds

- Begin taking deeper cuts as needed, keeping a consistent feed rate and depth of cut while monitoring both the condition of the cutting tool and workpiece carefully

- Finish by machining any desired features on the workpiece before coming to a stop and removing both fromthe lathe spindle safely

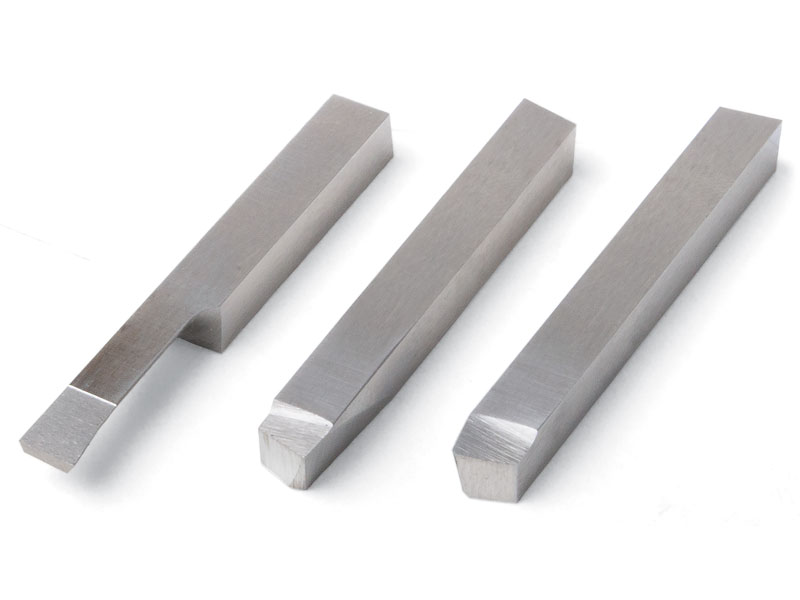

How to Make Lathe Cutting Tools

If you’re a fan of woodworking, then you know that a lathe is an essential tool for creating beautiful and intricate turned pieces. And if you’re new to the world of lathes, then you might be wondering how to make your own lathe cutting tools.In this blog post, we’ll show you how to make three different types of lathe cutting tools: a spindle gouge, a bowl gouge, and a parting tool.

Each of these tools has a specific purpose and will help you create different kinds of turned pieces.First, let’s start with the spindle gouge. This type of tool is used for making cylindrical shapes like candlesticks or table legs.

To make a spindle gouge, start with a piece of round stock that’s about 18 inches long. Then, use a metal-cutting saw to cut off one end at an angle so that it forms a point. Next, use a file to sharpen the other end of the tool until it’s nice and sharp.

Finally, put a handle on the Gouge by drilling two holes in the side and screwing in some wooden dowels or screws.Next up is the bowl gouge. This tool is used for carving out concave shapes like bowls or vases.

To make a bowl gouge, start with a piece of round stock that’s about 18 inches long. Cut off one end at an angle so that it forms a point and then use a file to sharpen the other end until it’s nice and sharp. Next, put a handle on the Gouge by drilling two holes in the side and screwing in some wooden dowels or screws .

Last but not least is the parting tool. This handy little tool is used for creating small grooves or slots in your workpiece . To make one , start witha piece of flat stock that’s about 6 inches long .

Cut off one end at an angle so that it forms ia point , then usea fileto sharpenthe other enduntilit ‘s niceandsharp .Puta handleon thistoolby drillingtwo holesin the sideandscrewingin somewoodendowelsor screws .With these three essential lathe cutting tools , you can create just about any kind of turned woodworking project imaginable ! So get creative and have fun !

Credit: www.sherline.com

How Do You Set a Tool on a Lathe?

Assuming you would like a blog post discussing how to set up different tools on a lathe:“How do you set a tool on a lathe?”There are many different ways to set up tools on a lathe, depending on the type of tool and the desired outcome.

In general, however, the process is fairly similar.First, the workpiece must be secured in the lathe’s chuck or faceplate. Next, the toolholder is inserted into the lathe’s turret or toolpost.

The toolholder should be tightened securely in place.Once the toolholder is in place, the cutting tool can be inserted into it. The cutting tool should also be tightened securely in place.

Some adjustments may need to be made at this point, such as setting the correct height or angle for the particular operation being performed.Finally, once everything is secure and in place, the lathe can be turned on and operated as usual.

How Do You Position a Cutting Tool on a Lathe?

When it comes to positioning a cutting tool on a lathe, there are three main things you need to take into account: the type of material you’re working with, the size and shape of the workpiece, and the specific cutting operation you’re performing.For most materials, you’ll want to position the cutting tool just below the centerline of the workpiece. This will help ensure that cuts are evenly distributed across the entire surface.

However, there are some exceptions to this rule – for example, when working with very soft materials or when making extremely shallow cuts.The size and shape of your workpiece will also affect how you position the cutting tool. For instance, if you’re working with a long and slender workpiece, you may need to adjust your positioning so that the cutting tool doesn’t vibrate excessively while in use.

Similarly, if you’re dealing with an irregularly shaped workpiece, you’ll need to be extra careful in order to avoid damaging it.Finally, keep in mind that different types of cutting operations require different positioning of the cutting tool. For example, when facing off a workpiece (i.e., removing material from its end), you’ll want to position the cutter slightly above center.

When threading or drilling holes, on the other hand, it’s often best to start from below center and then move up as needed.

How Do You Set Up a Lathe for Turning?

The first step is to determine what size workpiece you will be turning. The three most common lathe sizes are the mini lathe, midi lathe, and full-size lathe. Once you know the maximum diameter of the workpiece, you can choose the correct size tool bits and chucks.

Next, you need to set up the tool rest and tailstock. The tool rest should be positioned so that it is level with the centerline of the spindle. The tailstock should also be positioned so that it is level with the spindle.

To do this, you will need to adjust the height of the bed ways.Once the tool rest and tailstock are in place, you can install your chosen chuck onto the spindle. Make sure that the chuck is tightened securely before starting to turn your workpiece.

Now you are ready to start turning!

How Do You Set Up a Cutting Tool Machine?

If you’re interested in learning how to set up a cutting tool machine, there are a few things you’ll need to know. First, you’ll need to familiarize yourself with the different types of cutting tools and their respective sizes. Next, you’ll need to determine the correct type of machine for your specific project.

Finally, you’ll need to follow the manufacturer’s instructions for setting up the machine.The first step is understanding the different types of cutting tools available. There are three primary types: end mills, reamers, and taps.

Each has a different purpose and is available in a variety of sizes. End mills are designed for milling or drilling holes, reamers are used for enlarging existing holes, and taps create new threads in blind holes.Next, you’ll need to identify the best machine for your project.

If you’re only working on small projects, a handheld rotary tool will suffice. For larger projects, however, you’ll need a dedicated machine such as a lathe or milling machine. These machines are much more precise than rotary tools and can handle heavier cuts.

Finally, it’s time to set up your machine according to the manufacturer’s instructions.

Conclusion

Assuming you would like a summary of the blog post titled “How to Set Up a Lathe Cutting Tool”:The blog post explains the process for setting up a lathe cutting tool. First, the workpiece must be clamped in place.

Next, the cutting tool must be positioned at the correct height and angle. The author provides detailed instructions for how to do this. Finally, the speed of the lathe should be set correctly before starting to cut.