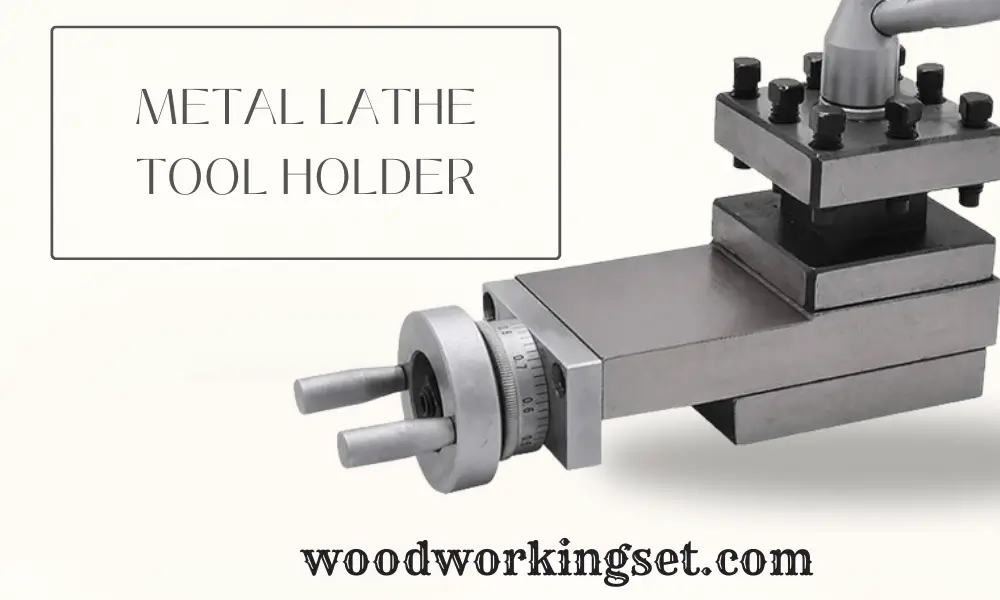

A metal lathe tool holder is an essential accessory in lathe operations. It is designed to securely hold and position various lathe tools for cutting, turning, and shaping metal workpieces. The tool holder acts as a mount and support for the cutting tools, allowing for precise and efficient machining processes. Without a reliable tool holder, it would be difficult to achieve the desired results in lathe operations.

What is a metal lathe tool holder?

Table of Contents

A metal lathe tool holder, also known as a lathe tool post, is a device used to hold and secure various types of lathe tools. It is typically mounted on the lathe carriage or turret and allows for quick and easy tool changes during machining operations. The tool holder consists of a base that is fixed to the lathe and a clamping mechanism that securely holds the tool in place.

Overview of lathe tool holders

Lathe tool holders come in various sizes and designs to accommodate different types of lathe tools. They are generally made from durable materials such as steel or carbide to withstand the forces involved in cutting metal. The tool holder is also designed to provide stability and rigidity to the cutting tool, ensuring precise and accurate machining.

Importance of tool holders in lathe operations

Tool holders play a crucial role in lathe operations. They provide a secure and stable platform for the cutting tool, allowing for precise and controlled cutting. Without a reliable tool holder, the cutting tool may vibrate or move during machining, leading to poor quality workpieces and potential damage to the lathe. Additionally, tool holders allow for easy and quick tool changes, saving valuable time in machining processes.

Different types of metal lathe tool holders

There are different types of metal lathe tool holders available, each designed for specific lathe operations and cutting requirements. Some of the commonly used tool holders include standard tool holders, indexable carbide tool holders, and boring bars.

What are the key features of a good lathe tool holder?

When choosing a metal lathe tool holder, there are several key features to consider:

Durability and strength of the tool holder

A good tool holder should be made from durable materials such as steel or carbide to withstand the forces involved in cutting metal. It should be able to withstand high cutting forces without flexing or deforming, ensuring stable and consistent machining.

Compatibility with different lathe tools

The tool holder should be compatible with a wide range of lathe tools, allowing for versatility in machining operations. It should be able to securely hold different types and sizes of cutting tools, such as turning tools, boring bars, and threading tools.

Adjustability and precision in tool placement

A good tool holder should provide precise and adjustable tool placement. It should have a mechanism for adjusting the position of the tool, allowing for precise machining and achieving the desired cutting dimensions. The tool holder should also provide a secure clamping mechanism to hold the tool firmly in place.

How to choose the right metal lathe tool holder?

Choosing the right metal lathe tool holder depends on several factors:

Determining the type of tool holder needed for turning operations

The type of metal lathe tool holder needed depends on the specific turning operations to be performed. Different tool holders have different designs and features that cater to specific cutting requirements. Consider the type of cutting, the diameter of the workpiece, and the desired surface finish when selecting a tool holder.

Considering the size and capacity of the lathe tool holder

The size and capacity of the lathe tool holder should match the size and capacity of the lathe machine. It should be able to accommodate the size and weight of the cutting tools without compromising stability and accuracy.

Choosing the right tool post for quick changes in tooling

For efficient and quick tool changes, consider a tool post that allows for easy and secure tool mounting. Quick-change tool posts, for example, provide a convenient way to switch between different cutting tools, minimizing downtime and maximizing productivity.

What are the different types of metal lathe tool holders available?

There are different types of metal lathe tool holders available, each designed for specific lathe operations:

Standard tool holders for general lathe operations

Standard tool holders are commonly used for general lathe operations. They come in various sizes and designs to accommodate different types of cutting tools. Standard tool holders provide stability and rigidity to the cutting tool, ensuring precise and accurate cutting.

Indexable carbide tool holders for versatile cutting options

Indexable carbide tool holders are designed for versatility in cutting options. They feature carbide inserts that can be rotated or replaced, allowing for different cutting angles and edge preparations. Indexable carbide tool holders are commonly used in machining operations that require versatile cutting capabilities.

Boring bars for internal machining and bores

Boring bars are specifically designed for internal machining and bores. They feature a long, slender design that allows for deep hole machining. Boring bars are commonly used in applications that require precise internal diameter machining, such as creating holes and bores with tight tolerances.

How to properly use and maintain a metal lathe tool holder?

Proper usage and maintenance of a metal lathe tool holder are essential for achieving optimal performance and longevity:

Tips for securely clamping tools in the tool holder

When clamping tools in the tool holder, ensure proper alignment and secure clamping. Make sure the cutting tool is positioned correctly and tightened securely using the clamping mechanism provided. Inspect the tool holder to ensure that it is free from any defects or damage that may affect tool mounting.

Cleaning and inspecting the tool holder for wear and damage

Regular cleaning and inspection of the tool holder are necessary to maintain its performance and prolong its lifespan. Remove any dirt, chips, or debris that may have accumulated in the tool holder. Inspect the tool holder for signs of wear, damage, or excessive tool marks. Replace any worn-out or damaged parts as needed.

Proper storage and maintenance of the lathe tool holder

When not in use, store the lathe tool holder in a clean and dry environment. Avoid exposure to excessive moisture, heat, or corrosive substances that may damage the tool holder. Apply a light coating of rust preventive oil or lubricant to prevent corrosion. Follow the manufacturer’s recommendations for proper maintenance and periodic inspection.