Table saw maintenance checklist includes regular cleaning, checking and replacing blades, lubricating moving parts and adjusting the blade. Proper maintenance of a table saw is crucial for its performance and longevity.

Neglecting maintenance can lead to poor sawing results, increased risk of accidents and costly repairs. In this article, we will provide you with a comprehensive table saw maintenance checklist, so you can ensure your saw is always in optimal condition.

By following these simple steps, you can prolong the life of your table saw and achieve accurate cuts every time.

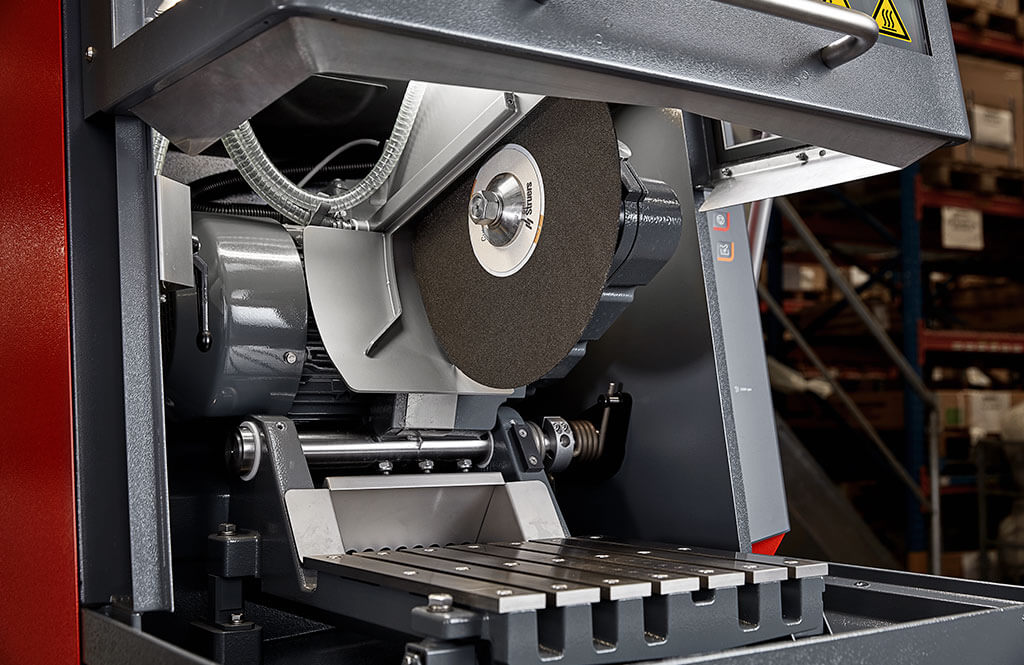

Credit: www.struers.com

Pre-Maintenance Checks:

Table of Contents

Performing regular maintenance on your table saw is essential to keep it functional and help it last longer. However, before you begin any maintenance work, it’s crucial to carry out some pre-maintenance checks. These checks ensure that the saw is in good working condition before you start your maintenance process.

Below are some essential pre-maintenance checks to conduct before carrying out any maintenance work on your table saw.

Inspecting The Components Of The Saw:

To perform the inspection, you need to disassemble the saw and examine each component. Here are the components to inspect:

- Blade: Check whether the blade is dull, chipped, or bent. If so, replace it immediately.

- Arbor: Check whether the arbor is clean and free of rust.

- Fence: Ensure that the fence is not bent, misaligned, or loose.

- Miter gauge: Check the miter gauge’s accuracy by aligning it with the blade.

- Motor belt: Check for any crack or wear on the motor belt.

Checking The Alignment Of The Blade And Fence:

Accurate blade and fence alignment is essential for precision cutting. Here are the steps to check the blade and fence’s accuracy:

- Blade alignment: Use a digital gauge or dial indicator to check whether the blade is parallel to the miter slot.

- Fence alignment: Use a combination square to check whether the fence is at a 90-degree angle to the table surface. Also, ensure that the fence is parallel to the blade.

Ensuring The Safety Features Are In Good Condition:

Safety features are essential to prevent accidents and injuries. Therefore, it’s crucial to ensure the safety features are in good working condition before performing any maintenance work. Here are the safety features to check:

- Blade guard: Ensure that the blade guard is attached properly and moves freely.

- Riving knife: Check whether the riving knife is correctly aligned with the blade.

- Anti-kickback pawls: Ensure that the anti-kickback pawls are in good working condition.

Pre-maintenance checks are vital to ensure that your saw is in good working condition before carrying out maintenance work. By performing these pre-maintenance checks, you can prevent damage to your saw and ensure that it performs optimally.

Cleaning The Saw:

The Importance Of Regular Cleaning

If you’re serious about using your table saw for top quality projects, keeping it clean is essential. Regular cleaning helps prevent dust and debris from building up in your saw, which can negatively impact the accuracy of its cuts. Not only does a dirty saw create a mess, but over time, it may also affect its functionality and lifespan.

Necessary Tools/Materials For Cleaning

To clean your saw adequately, you’ll need a few items. These may include:

- Safety goggles, gloves, and a dust mask

- A dust brush or compressed air

- A clean, dry cloth or towel

- Appropriate cleaning solutions

Best Practices For Removing Debris And Dust

Here are some best practices for cleaning your saw:

- Before beginning any cleaning, ensure the saw is switched off and unplugged.

- Wear appropriate personal protective equipment (ppe), such as safety goggles, gloves, and a dust mask.

- Use a dust brush or compressed air to remove large debris and dust build-up on the saw’s surface and in the motor housing.

- Use a damp cloth with an appropriate cleaning solution to wipe down the surface and remove any residual dirt.

- Allow the saw to dry completely before turning it back on.

Cleaning your table saw is an essential task that should not be overlooked. With adequate care and maintenance, you can ensure that your saw remains accurate, functional, and safe for extended periods. These simple steps can help protect your investment and contribute to the longevity of your equipment.

Lubrication:

The Importance Of Lubrication In Maintaining A Saw

Proper maintenance of your table saw is essential to ensure optimal performance. One key aspect of maintenance is lubrication. Lubricating your saw regularly not only extends its lifespan but also helps to prevent accidents. By reducing friction between parts, lubrication ensures smooth operation of the machine and prevents wear and tear.

Best Practices For Lubricating The Saw

Proper lubrication techniques are crucial to maintain the longevity of your table saw. Here are some best practices to follow:

- Oil the saw blade: This not only reduces friction but also prevents rust buildup. Use a cloth to apply oil on the blade evenly.

- Lubricate moving parts: The trunnion assembly, arbor assembly, gears, and bearings should be lubricated regularly to ensure smooth operation.

- Choose the right lubricant: Always use a lubricant recommended by the manufacturer. The wrong type of lubricant can damage your saw.

- Apply lubricant as per manufacturer’s instructions: Avoid over-lubricating the machine, as it can attract dust and debris.

- Clean the saw regularly: Before applying lubricant, make sure the machine is thoroughly cleaned. This prevents dirt and debris from getting into the lubrication system.

By following these best practices, your saw will be well maintained and last for many years. Proper lubrication techniques will also help to prevent accidents and ensure your safety when using the machine.

Remember to always refer to the manufacturer’s manual and follow their instructions when maintaining your saw. Neglecting regular maintenance and lubrication can lead to costly repairs and even accidents. So, take care of your table saw and it will take care of you.

Maintenance Schedule:

Developing A Maintenance Schedule

As a table saw owner, maintaining your machine is crucial to ensure it’s working effectively and safely. However, maintaining a table saw can become overwhelming, especially when you don’t know where to start. That’s why it’s critical to develop a maintenance schedule that outlines specific times and tasks.

Frequency Of Checks And Maintenance Tasks

Here are some essential tasks to include in your maintenance schedule, along with recommended frequencies:

- Clean the table saw: Regular cleaning of the table saw is necessary to prevent dust and other debris from accumulating. Clean the saw after every use or at least once a week.

- Check the blade alignment: A misaligned blade can result in a poor cut or even a dangerous situation. Check the blade alignment monthly or every time you change the blade.

- Inspect the blade: Inspect the blade for any cracks, chips, or missing teeth before each use.

- Adjust the fence: The fence guides the workpiece and needs to be adjusted to ensure accurate cutting. Check the fence alignment monthly or every time you change the blade.

- Lubricate parts: Lubricate critical parts like the blade lift assembly, elevation and tilt mechanisms, and trunnions. Depending on the frequency of use, lubricate every six months to one year.

Importance Of A Maintenance Schedule

Developing a maintenance schedule for your table saw can save you time and money in the long run. A well-maintained table saw performs better and lasts longer, reducing the need for costly repairs or replacement. Additionally, regular maintenance ensures that your table saw is safe to use, reducing the risk of injury.

So, take the time to establish a maintenance plan, and your table saw will perform at its best for years to come.

Troubleshooting Common Issues:

Overview Of Common Problems With A Table Saw

As a woodworker, experiencing problems with your table saw could be frustrating, time-consuming, and costly. A few common issues may surface when operating a table saw, which mainly depends on how well you maintain it. Here are a few problems you need to be aware of when dealing with a table saw:

- Blunt blade

- Aligning issue

- Motor problems

- Dust collection

- Fence and miter gauge.

Causes And Solutions To These Issues

A table saw is a complicated tool with many parts made up of mechanical and electrical components. Identifying the cause of the problem is the first step in troubleshooting a malfunctioning table saw. Here are the causes and solutions to the most common table saw problems:

- Blunt blade:

- Cause: A dull saw blade can cause burns on the wood, and it can cause the saw blade to start smoking.

- Solution: Change the blade with a sharp one, keep the blade clean, or sharpen the blade professionally.

- Aligning issues:

- Cause: Misalignment of the table saw blade, fence, or miter gauge.

- Solution: Use a straight edge to check for misalignment, adjust the table saw accordingly, and use shims to ensure the table saw is level.

- Motor problems:

- Cause: Motor burnout, faulty switches, or bad capacitors.

- Solution: Replace any faulty parts, and lubricate any parts that require greasing.

- Dust collection:

- Cause: Poor dust collection can result in clogged filters, less efficient motor, and a potential fire hazard.

- Solution: Clean the filters regularly, optimize dust hose attachment, and use an air filtration system.

- Fence and miter gauge:

- Cause: Loose or misaligned fence can cause inaccuracy or kickback.

- Solution: Check the fence and miter gauge for alignment, and tighten screws or bolts where required.

Troubleshooting Common Problems With A Table Saw

While the above tips are essential for maintaining and troubleshooting problems with your table saw, sometimes, things may not go as planned. Troubleshooting your table saw issues can be a frustrating process, but it is essential to fix any problems so that you can work safely and effectively.

Here are some additional troubleshooting tips to help you get back to woodworking:

- Check the manual for any helpful troubleshooting tips.

- Use diagnostic quizzes or checklists to help identify table saw problems.

- Reach out to a professional to help diagnose and fix any problems you cannot solve.

Now that you have an overview of common issues, what causes these issues, and how to troubleshoot them, you can work with confidence and safety on your table saw. Remember to prioritize safety and never compromise on your woodworking quality.

Frequently Asked Questions Of Table Saw Maintenance Checklist

What Should Be Included In A Table Saw Maintenance Checklist?

A table saw maintenance checklist should include checking the blade alignment, cleaning the saw’s interior and exterior, inspecting the electrical connections, and lubricating the moving parts of the saw.

How Often Should A Table Saw Be Maintained?

It is recommended that a table saw undergo routine maintenance every 3-6 months depending on the frequency of use. A thorough cleaning and lubrication should be done after every use.

Why Is Blade Alignment Important In Table Saw Maintenance?

Proper blade alignment ensures accuracy, easy cutting, and reduces the risk of kickback. Misaligned blades can cause cuts to be off by fractions of an inch, which can affect the precision and safety of your cuts.

What Type Of Lubricant Should Be Used For Table Saw Maintenance?

A silicone-based lubricant is ideal for table saw maintenance as it is not affected by temperature fluctuations, does not attract dust, or gum up the moving parts of the saw.

Can I Perform Table Saw Maintenance Myself Or Should I Hire A Professional?

Table saw maintenance can be performed by the owner if they have the proper knowledge and tools. However, if you are not confident in your ability, it is recommended that you hire a professional for safety reasons.

Conclusion

Maintaining your table saw is critical to ensure smooth and consistent performance. A well-maintained table saw will last for years and provide you with accurate and safe cutting experience. Remember to keep the blade sharp and clean, the table clean and free of debris, the fence aligned and secure, the motor lubricated, and the safety features intact.

By following this maintenance checklist, you can keep your table saw in top-notch condition and prevent costly repairs or accidents. Make it a habit to inspect your table saw regularly and address any issues promptly. Don’t forget to refer to your owner’s manual for specific instructions and recommendations.

With proper care and maintenance, your table saw can continue to be a valuable investment and a reliable tool in your workshop. Happy cutting!