You can make a 67.5-degree cut with a table saw. In this column, we’ll show you how to do it quickly and easily. Many people are afraid to use a table saw, but it’s actually not that difficult. Once you know how, you’ll be able to cut all kinds of curves with ease! Let’s learn how to use a table saw to make a 67.5-degree cut!

What’s the best way to make a 67.5-degree cut on a table saw?

A compound miter saw is the best tool for making a 67.5-degree cut on a table saw. That’s right—you can set the saw to cut at 45 degrees and then make two cuts at 22.5 degrees. This will give you a full 67.5 degrees.

To quickly explain how to do it, here it is:

- Find the exact point on your workpiece and mark it.

- Make sure your table saw blade is at the correct angle.

- Cut along the line that was drawn.

- Smooth out any rough edges with a knife or hand plane. Bye! Soon, you’ll be able to cut a perfect curve every time using your table saw.

How do you measure the angle to make sure you’re cutting it correctly?

You can do this a few different ways. You can use a protractor to figure out how long the sliver is or you can just use your hand. First, divide the length by two. Then, use that answer.

Use a scale to figure out the length of the sliver, and then use a protractor to find the angle that goes with that length. This will give you the most accurate measurement. For example, if your thin slice is half an inch long, you’ll want to set the protractor about 11 degrees lower.

What are some tips for cutting a 67.5-degree angle correctly?

It’s not important to worry about cutting a 67.5-degree angle correctly. Here are some ideas that can help:

- Use a saw with very sharp teeth. With a very sharp blade, you can make clean, precise cuts.

- Always use a level or straightedge. This will ensure that the cut you are making is straight.

- When cutting, measure twice and then cut once! Before cutting, make sure you have the right measurements. Once the wood is set, there is no going back!

- Hold the piece you are cutting with a clamp. This will help you cut with more control and skill.

- If you need to, cut a piece of scrap paper to get used to it before cutting the real thing.

Can you tell us more about how to make this type of cut safely?

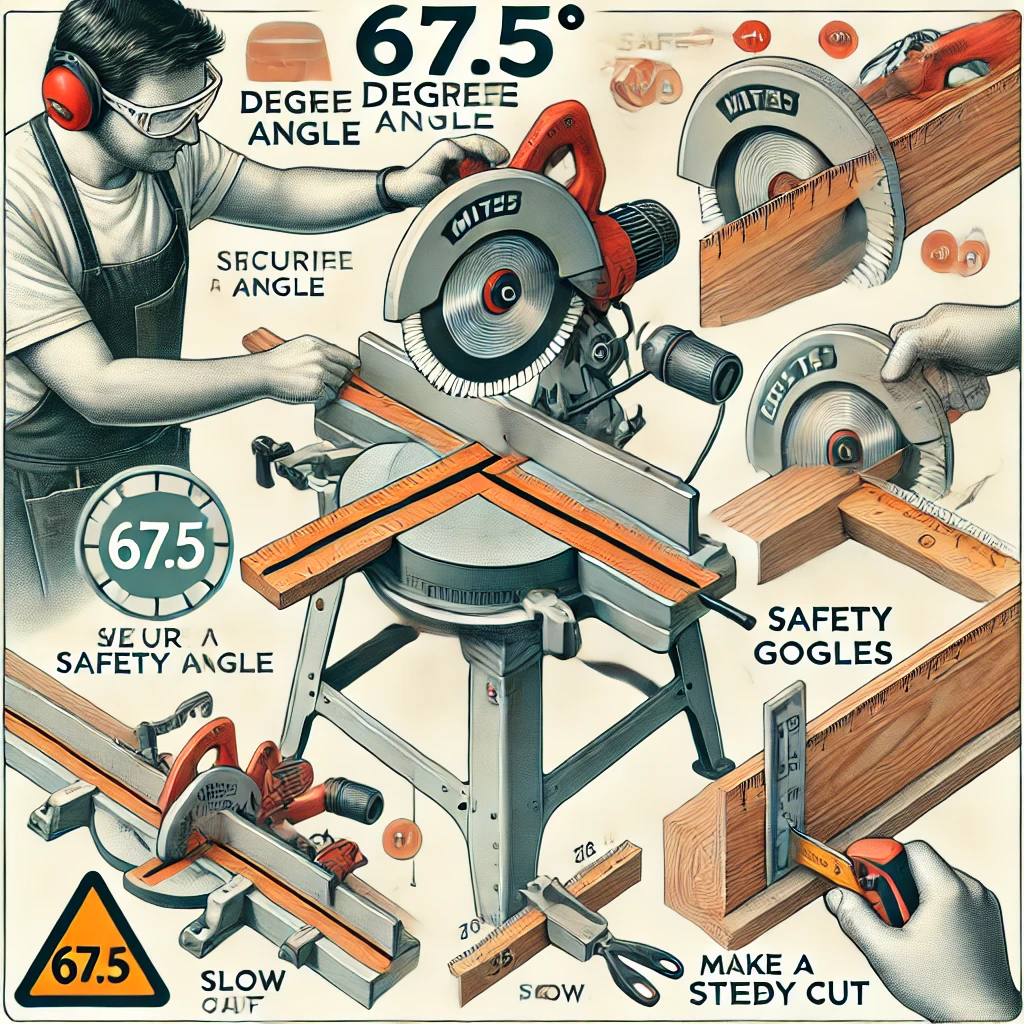

There are several safe ways to make this cut. You will need a miter saw blade to use with a 67.5-degree miter saw. Place the blade on a table saw and tilt it 45 degrees the other way. Use a saw and cut along the lines drawn on the wood with a Sharpie pen (or something similar). This is the third way.

When cutting wood, no matter what method you choose, be sure to wear safety glasses and gloves, and always follow the tool manufacturer’s instructions. Also, be careful not to cut yourself or anyone else while doing this!

How do you set your saw to cut at a 67.5-degree angle?

Here’s how to set your saw to cut at a 67.5-degree angle:

- First, use a straight edge and a sharp pencil to measure and mark the angle you want on your work piece.

- After making the mark, adjust the height of the blade so that it lines up with it.

- Then, remove the clamp from the blade and tilt it until it is at the same angle as the angle you found in step one. Tighten the blade clamp once.

What type of blade should you use for a 67.5-degree angle?

If you want to cut at a 67.5-degree angle, you should use a circular saw blade. This type of blade produces the best cuts, and it is also the easiest to use. Do not use a miter saw blade; it will not work properly and may damage your saw.

How do you hold the material when cutting with a table saw?

Hold the material with both hands and keep your fingers away from the blade.

When cutting with a table saw, you should always use both hands. This will allow you to keep your fingers away from the blade and thus have a better view of the material. Do not place your fingers in front of the blade. Instead, place them behind the guard.

Is there a specific cutting length that is best for a 67.5-degree angle?

There is no clear answer to this question because the best cutting length depends on many things, such as the type of wood you are using and your tools. However, it is generally better to cut shorter items than longer ones. Shorter items are more accurate and less likely to make mistakes, while longer items can be harder to control and can cause problems.

Is there any other way to cut a 67.5 degree angle without using a table saw?

Yes. If you have one, you can use a circular saw to create a 67.5 degree angle. Before you start cutting, make sure the blade is level and the saw is aligned with the mark you want to make.

If you don’t want to use a circular saw, you can cut the angle with a miter saw or jigsaw. However, these tools are difficult to use and may not give you the exact results you want. And finally, if you want to try something new, you can cut the angle with a hand saw, but it will probably be harder to use than other tools.

How do you cut a large angle on a table saw?

Before you can cut a large angle, you need to enlarge the blade on a table saw. You can do this by installing a new blade or making some modifications to the old one. After installing the blade, make sure the table saw is securely in place, and then start cutting. Make sure you move slowly and carefully so you don’t hurt yourself or the material you’re cutting. It’s always better to be safe than sorry when cutting curves with a table saw.

FAQ,s: [Frequently Asked Questions]

How should I set my table saw to make a 67.5 degree cut?

To begin, use an angle finder or protractor to set the miter gauge or tilt the blade to exactly 67.5 degrees.

Is there anything else I can use besides a table saw to make a 67.5< angle cut?

If you’re careful, you can use tools like a chisel and a hand saw, as well as a miter saw and a circular saw with an adjustable bevel.

What types of wood work best for cutting corners?

Softwoods like pine can easily splinter, while hardwoods like oak or maple tend to produce clean cuts due to their density.

How do I make sure that the cuts I make are accurate when working with large pieces of wood?

To keep large pieces of wood stable, use support stands or rollers, and before cutting the final piece, you may want to make some test cuts on scrap wood.

In conclusion:

Goodbye! You now know how to make a 67.5-degree angle cut using your table saw. So make sure you practice this skill a lot and become proficient at it. It will help you in many woodworking tasks. If you have any questions about the steps we have outlined or need help completing this task, please do not hesitate to contact us. Thanks for reading, and enjoy cutting wood!