When it comes to machining and manufacturing, the lathe machine holds a significant place. It is an essential tool in various industries for shaping and cutting materials with precision. But why is a lathe called a machine tool? In this article, we will explore the definition, working principles, and historical significance of the lathe machine to better understand why it is considered a machine tool.

What is a Lathe Machine?

Table of Contents

Definition of a Lathe Machine

A lathe machine is a powerful tool used in the machining process to shape and cut various workpieces. It consists of a rotating spindle that holds the workpiece and a cutting tool that removes material to create the desired shape. Lathes are known for their versatility and ability to handle different materials, including wood, metal, and plastics.

How Does a Lathe Machine Work?

A lathe machine operates on the principle of rotational motion. The workpiece is securely mounted on the spindle, which rotates at high speeds. The cutting tool, positioned in close proximity to the workpiece, moves along its length and removes material to shape it. This process allows for precise and controlled machining operations.

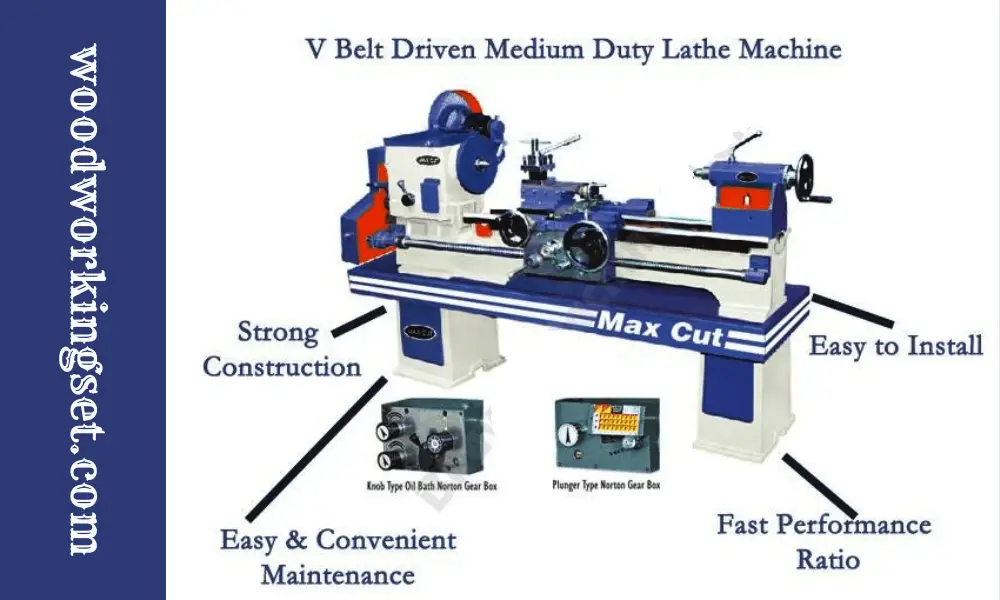

Parts of a Lathe Machine

A lathe machine consists of several key components that work together to facilitate the machining process. These include the headstock, which houses the main spindle and motor, and the tailstock, which provides support to the workpiece. The tool post holds the cutting tool, enabling it to move during machining. Other important parts include the cross slide, compound rest, and lathe bed.

What is a Machine Tool?

Definition of a Machine Tool

A machine tool is a device used to shape, cut, or deform materials. It is often powered by electricity or hydraulic systems and encompasses a wide range of tools, including lathes, milling machines, drills, and grinders.

Difference Between a Machine and a Machine Tool

Although the terms “machine” and “machine tool” are sometimes used interchangeably, there is a subtle difference between the two. A machine refers to any device capable of performing a specific task, while a machine tool is a specific type of machine designed for shaping or cutting materials.

Types of Machine Tools

The term “machine tool” encompasses various types of machines used in different industries. Some common examples include lathes, milling machines, drills, and grinding machines. Each type of machine tool has its unique capabilities and applications.

Why is Lathe Called a Machine Tool?

Historical Significance of Lathe

The lathe machine has a rich history dating back to ancient times. It was one of the first machines invented by humans to shape and cut materials. The earliest lathes were powered by human or animal labor, but with the advent of the Industrial Revolution, they became mechanized.

Lathe as the “Mother of All Machine Tools”

The lathe machine holds a special place in the history of machine tools. It is often referred to as the “mother of all machine tools” because it laid the foundation for the development of other machines. Many modern machine tools, such as milling machines and drills, have their origins traced back to the lathe.

Lathe’s Role in the Machine Shop

In a machine shop, the lathe machine plays a pivotal role. It is used for a wide range of machining operations, including turning, facing, drilling, and taper turning. Its versatility and precision make it an indispensable tool for producing various components and parts used in different industries.

How Does Lathe Work?

The Cutting Process on a Lathe

On a lathe machine, the cutting process involves the rotation of the workpiece while a cutting tool removes material. The cutting tool can be either a single-point tool or a multipoint tool, depending on the desired outcome. The cutting speed, feed rate, and depth of cut are carefully controlled to achieve the desired shape and surface finish.

Tools Used on a Lathe

A wide variety of tools can be used on a lathe machine, depending on the specific machining operation. Some common tools include turning tools, boring tools, parting tools, and drilling tools. These tools come in different shapes and sizes to accommodate various workpiece geometries and material types.

Common Workpieces on a Lathe

Lathes are used to shape and cut a wide range of workpieces. In the metalworking industry, common workpieces include shafts, cylinders, and rings. In woodworking, lathes are used to create decorative pieces such as bowls, vases, and furniture legs. The versatility of the lathe machine allows for endless possibilities in terms of workpiece design and functionality.

Different Types of Lathes

Engine Lathe

The engine lathe is the most common type of lathe machine. It is used for a wide range of machining operations and offers great flexibility and precision. Engine lathes are often found in workshops and tool rooms due to their versatility and reliability.

Turret Lathe

A turret lathe is a type of lathe machine equipped with a turret tool head. It allows for rapid tool changes and enables the machining of complex workpieces with multiple operations. Turret lathes are commonly used in high-volume production environments.

CNC Lathe

A CNC lathe machine is a computer-controlled lathe that offers exceptional precision and automation. It allows for complex machining operations with minimal manual intervention. CNC lathes are widely used in industries where high precision and efficiency are required.

Other Key Concepts in Lathe & Machine Tools

Tool Post

The tool post is an essential component of a lathe machine. It holds the cutting tool securely in place, allowing for precise machining operations. Different types of tool posts are available, such as quick-change tool posts, which enable rapid tool changes.

Drill on a Lathe

A drill can also be used on a lathe machine to create holes in workpieces. Drilling on a lathe provides greater accuracy and alignment compared to standalone drilling machines. It is commonly used for creating holes with precise depths and diameters.

Axis and Spindle in Lathe

In a lathe machine, the axis refers to the line around which the workpiece rotates. The spindle is the component responsible for rotating the workpiece. Both the axis and spindle are critical for achieving accurate and symmetrical machining operations.

The Importance of Lathe Work

Lathe’s Contribution to Various Industries

The lathe machine plays a crucial role in various industries, including automotive, aerospace, and manufacturing. It is used to produce a wide range of components and parts, such as engine cylinders, gear shafts, and turbine blades. Without the lathe machine, the production of these critical components would be significantly more challenging and less precise.

The Role of Lathe in Precision Machining

When it comes to precision machining, the lathe machine is one of the primary tools. Its ability to achieve tight tolerances and excellent surface finishes makes it indispensable for manufacturing parts that require high precision. From medical devices to precision instruments, the lathe machine plays a vital role in ensuring the quality and accuracy of these components.

Lathe Work and Craftsmanship

Lathe work is not just limited to industrial applications. It is also highly valued in the field of craftsmanship and art. Woodturning, for example, involves using a lathe machine to shape and create intricate designs in wooden objects. The lathe allows artisans to express their creativity and produce unique pieces of art.